- Home

- Products

- CNC Lathe

- Flat Bed CNC Lathe

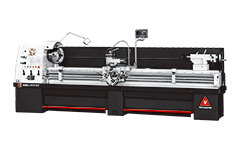

- CRL Series Flat Bed CNC Automatic Lathe

CRL Series Flat Bed CNC Automatic Lathe

| MODEL | CRL-1440 | CRL-1640 | CRL-1660 | ||

|---|---|---|---|---|---|

| Capacity | No. of control axis | 2 AXIS | |||

| Swing over bed | Ø360 mm (14.17") | Ø410 mm (16.14") | Ø410 mm (16.14") | ||

| STD. D1-6 distance between centers | 890 mm (35") | 890 mm (35") | 1400 mm (55") | ||

| STD. D1-6Max. working length | 4 way tool post | 750 mm (29.52") | 750 mm (29.52") | 1260 mm (49.61") | |

| Hyd. P8 turret | 630 mm (24.80") | 630 mm (24.80") | 1140 mm (44.88") | ||

| Max. working dia. | 4 way tool post | Ø170 mm (6.7") | Ø220 mm (8.66") | ||

| Hyd. P8 turret | Ø160 mm (6.29") | Ø210 mm (8.27") | |||

| Width of bed | 260 mm (10.236") | ||||

| Headstock and Main Spindle | Spindle nose, internal taper | STD. D1-6, MT. No.6 OPT. A1-6, MT. No.6 | |||

| Spindle bore | STD. Ø52.5mm (2.066") OPT. Ø51mm (2") | ||||

| Spindle speed | Gear steps | Pneumatic change 2 steps / | L 25~480 R.P.M. | ||

| Range | H 481~3000 R.P.M. | ||||

| Cross Slide (X-axis) and Carriage (Z-axis) | Cross slide travel ( X-axis ) STD. | 205 mm (8.07") | 205 mm (8.07") | 205 mm (8.07") | |

| Longitudinal travel ( Z-axis ) STD. | 815 mm (32.08") | 815 mm (32.08") | 1325 mm (52.16") | ||

| AC servo motor ( X-axis ) | 0.75 kW 3.5 N.m | ||||

| AC servo motor ( Z-axis ) | 1.20 kW 7.0 N.m | ||||

| Dia. of ball screw ( X-axis) | Ø20 mm (0.787") P5 C5 | ||||

| Dia. of ball screw ( Z-axis ) | Ø32 mm (1.259") P10 C5 | ||||

| Rapid traverse speed ( X-axis ) | 7.5 m/min (295.3 ipm) | ||||

| Rapid traverse speed ( Z-axis ) | 10 m/min (393.7 ipm) | ||||

| Turret | Tool station | STD. Manual 4 way tool post ☐20 mm | OPT. Elec H4 turret ☐20 mm or Hydraulic P8 turret ☐20 mm Ø20 mm (0.787") |

||

| Size of external turning tool | |||||

| Boring bar diameter | |||||

| Tailstock | Quill diameter | Ø58 mm (2.283") | |||

| Quill travel | 140 mm (5.5") | ||||

| Taper of center | MT.No.4 | ||||

| Motor | Main spindle | 5.5kW/7.5kW (30min, rated) | |||

| Hydraulic oil pump | OPT. 0.75 kW (1 HP) OPT. 1.5kW (2HP) | ||||

| Forced lubrication for headstock | 1 / 4 HP | ||||

| Coolant pump | 1 / 6 HP | ||||

| Tank Capacity | Hydraulic tank | OPT. 40 Litre (8.8 gal.) | |||

| Coolant tank | 50 L (11 gal) | 70 L (15.4 gal) | |||

| Measurements | Weight ( Net / Gross ) Approx. | 2,100 kgs / 2,600 kgs | 2,150 kgs / 2,650 kgs | 2,250 kgs / 2,750 kgs | |

| Packing sizes | Length | 2470 mm (97.24") | 2980 mm (117.32") | ||

| Width x Height | Width 2030 mm (79.92") x Height 2200 mm (86.61") | ||||

Standard Accessories:

- CNC controller:FANUC 0i Mate - TC

- CNC controller

- Rotating center MT.4

- Level pads - 8pcs

- Tool set and box

- Machine light

- Operation manual and parts list

Optional Accessories:

- 3-Jaws scroll 8" chuck

- 4-Jaws independent 10" chuck

- Electric H4 turret

- Hydraulic P8 turret with

boring bar holder Ø20 mm...2 sets

boring bar holder Ø25 mm....1 set

O.D / facing tool holder.....4 sets

I.D / facing tool holder........1 set - Boring socket Ø6 xØ20~Ø16 x Ø20

- Drilling socket MT.1 x Ø20

- Steady rest w / ball bearing

- High pressure coolant pump 3bar 750W

- Quick change tool post

- Hydraulic tailstock quill

- Chip conveyor & chip bucket cart

- Hydraulic hollow chuck 8" with rotary cylinder / bar capacity Ø40 for A1-6 spindle only

(Working length increased more 25mm)

Efficient, Accurate Power Turret (Optional)

- The electric H4 turret is driven by a worm gear/worm wheel mechanism for convenient tool change. It is powered by a 375 W. motor with great clamping force up to 1 ton.

- Specially designed post body prevents coolant and chips getting into post. Body will not move up and down during indexing.

- P8 hydraulic turret and quick change tool post are also available upon request.

Headstock

- Rugged headstock and gears are hardened by MAAG or REISHAUER. Ground for smooth, quiet and vibration-free running.

- Pressurized cyclic lubrication from separate electric pump and oil reservoir provides a constant flow to all gears and bearings which maintains excellent thermal stability. Hot oil does not stay in the headstock thus reducing thermal expansion and workpiece intolerance.

- The 4 parallel V-belt assures drive in extremely stable, smooth running with minimum vibration.

Convenient Manual Control

- Providing convenient manual control for X, Z axis. Moveable operation control box is also equipped with two electronic handwheels.

- Comprehensive, waterproof function keys and push buttons enhance operational convenience.