- Home

- Products

- CNC Lathe

- Flat Bed CNC Lathe

- CNC Series Flat Bed CNC Lathe

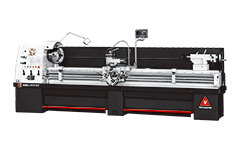

CNC Series Flat Bed CNC Lathe

| MODEL | CNC-1440 | CNC-1640 | CNC-1660 | ||

|---|---|---|---|---|---|

| Capacity | No. of control axis | 2 AXIS | |||

| Swing over bed | Ø360 mm (14.17") | Ø410 mm (16.14") | Ø410 mm (16.14") | ||

| Distance between centers (Manual tailstock) |

910 mm (35.82") | 910 mm (35.82") | 1420 mm (55.9") | ||

| Max. working length | 4 way tool post | 700 mm (27.55") | 700 mm (27.55") | 1210 mm (47.63") | |

| Hyd. P8 turret | 680 mm (26.77") | 680 mm (26.77") | 1190 mm (46.85") | ||

| Max. working dia. | 4 way tool post | Ø170 mm (6.7") | Ø220 mm (8.66") | ||

| Hyd. P8 turret | Ø160 mm (6.29") | Ø210 mm (8.27" ) | |||

| Width of bed | 260 mm (10.236") | ||||

| Headstock and Main Spindle | Spindle nose, internal taper | ASA A2-5 , Ø52mm Taper 1/19.18 | |||

| Spindle bore / Bar capacity | Ø46mm (1.811") / Ø36mm (1.417") | ||||

| Range of spindle speed No. of spindle speed |

40~5000 R.P.M. Infinitely variable |

||||

| Cross Slide (X-axis) and Carriage (Z-axis) | X-axis travel | 4 way tool post | 205 mm (8.07") | 205 mm (8.07") | |

| Hyd. P8 turret | 167 mm (6.57") | 178 mm (7") | |||

| Z-axis travel | 4 way tool post | 865 mm (34") | 865 mm (34") | 1375 mm (54") | |

| Hyd. P8 turret | 710 mm (27.95") | 710 mm (27.95") | 1220 mm (48.03") | ||

| AC servo motor ( X-axis ) | 0.75 kW 3.5 N.m~FANUC s4 / 4000is | ||||

| AC servo motor ( Z-axis ) | 1.2 kW 7.0 N.m~FANUC s8 / 3000is | ||||

| Dia. of ball screw ( X-axis) | Ø20 mm (0.787") P5 C5 | ||||

| Dia. of ball screw ( Z-axis ) | Ø32 mm (1.259") P10 C5 | ||||

| Rapid traverse speed ( X-axis ) | 7.5 m/min (295.3 ipm) | ||||

| Rapid traverse speed ( Z-axis ) | 10 m/min (393.7 ipm) | ||||

| Turret | Tool station | STD. Manual 4 way tool post ☐20 mm |

OPT. Electric H4 ☐20 mm or Hydraulic P8 ☐20 mm Ø20 mm (0.787") |

||

| Size of external turning tool | |||||

| Boring bar diameter | |||||

| Tailstock | Manual style | Quill diameter | Ø58 mm (2.283") | ||

| Quill travel | 140 mm (5.5") | ||||

| Taper of center | MT.No.4 | ||||

| Motor | Main spindle motor | STD.5.5kW / 7.5kW (30min, rated) OPT. 7.5kW / 11kW (30min. rated) | |||

| Hydraulic oil pump | STD. 0.75 kW (1 HP) OPT. 1.5 kW (2 HP) | ||||

| Coolant pump | 1 / 6 HP | ||||

| Tank Capacity | Hydraulic tank | 40 Liter (8.8 gal) | |||

| Coolant tank | 50 L (11 gal) | 70 L (15.4 gal) | |||

| Measurements | Weight ( Net / Gross ) Approx. | 2,100 kgs / 2,600 kgs | 2,150 kgs / 2,650 kgs | 2,250 kgs / 2,750 kgs | |

| Packing sizes | Length | 2,680 mm (105.51") | 3190 mm (125.6") | ||

| Width x Height | Width 2030 mm (79.92") x Height 2200 mm (86.61") | ||||

Specifications subject to change without notice.

Standard Accessories:

- CNC controller:FANUC 0i Mate - TC

- Hydraulic chuck 6" with rotary cylinder

- Rotating center MT.4

- Level pads --- 10pcs

- Tool set & box

- Machine light

- Operation manual and parts list

Optional Accessories:

- Electric H4 turret

- Hydraulic P8 turret with

boring bar holder Ø20 mm......2 sets

boring bar holder Ø25 mm......1 set

O.D / facing tool holder......4 sets

I.D / facing tool holder......1 set - Boring socket Ø6 x Ø20 ~ Ø16 x Ø20

- Drilling socket MT.1 x Ø20

- Steady rest w / ball bearing

- High pressure coolant pump 3bar 750W

- Quick change tool post

- Hydraulic tailstock quill

- Chip conveyor & chip bucket cart

Efficient, Accurate Power Turret (Optional)

- The electric H4 turret is driven by a worm gear/worm wheel mechanism for convenient tool change. It is powered by a 375 W. motor with great clamping force up to 1 ton.

- Specially designed post body prevents coolant and chips getting into post. Body will not move up and down during indexing.

- P8 hydraulic turret and quick change tool post are also available upon request.

Direct-driven Main Spindle Motor

- The spindle is supported by a single cylinder bearing housing equipped with SP level precision angular contact thrust bearings and lubricated with HI-class grease. The front spindle is designed with a labyrinthian collar and protector cover to prevent the entering of coolant or chips.

- Encased in a well-ribbed headstock for maximum heat dissipation. Prevents any thermal distortion after long periods of turning thereby ensuring accurate cutting.

Tailstock

- Rigid construction and increased throat depth on tailstock with MT#4 interior taper quill. When applying manual 4-way tool post, electric H4 turret or hydraulic P8 turret, it allows free cutting of long workpieces. When performing manual drilling, the quill can be set to zero for drill depth measurement. Can by optionally equipped with a hydraulic quill to automatically forward and reverse.