- Home

- Products

- Manual Lathe

- All Gear-Head Lathe

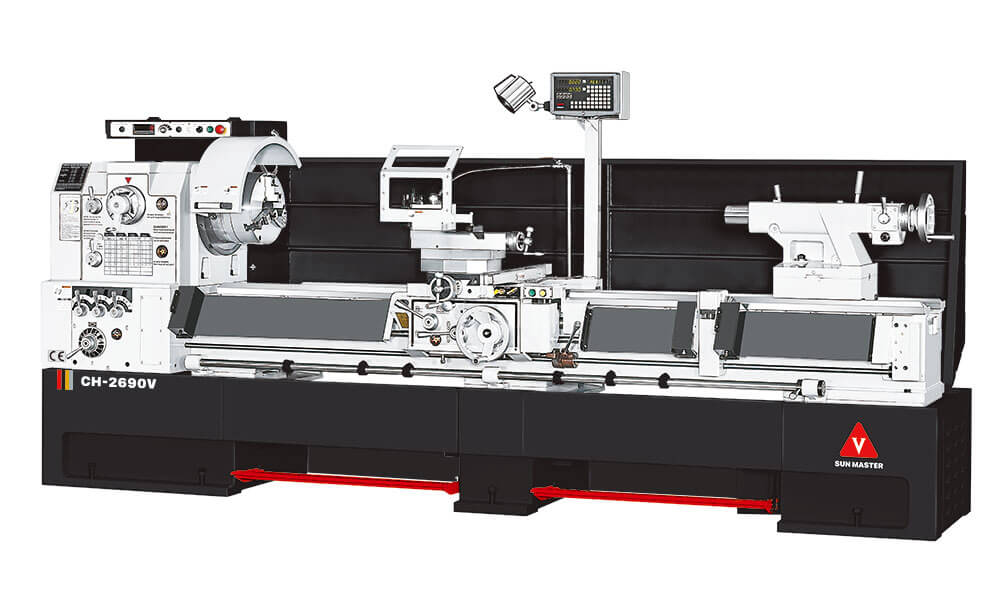

- CH Series Gear Head Manual Engine Lathe Machine

CH Series Gear Head Manual Engine Lathe Machine

Specification sheet of CH series Oil-Field lathe

| Model | CH-2260 / 2290 / 22120 22160 / 22200 | CH-2660 / 2690 / 26120 26160 / 26200 | CH-3060 / 3090 / 30120 30160 / 30200 | |||

|---|---|---|---|---|---|---|

| Capacity | ||||||

| Swing over bed | 560 mm (22") | 660 mm (26") | 760 mm (30") | |||

| Swing in gap | Ø797 mm (31.37") | Ø892 mm (35.11") | Ø990 mm (38.97") | |||

| Swing over cross slide | Ø340 mm (13.38") | Ø445 mm (17.51") | Ø548 mm (21.57") | |||

| Gap width in front of faceplate | 270 mm (10.63") | |||||

| Distance between centers | 1500 mm (60"), 2300 mm (90"), 3000 mm (120"), 4000 mm (160"), 5000 mm (200") | |||||

| Width of bed | 400 mm (15.75") | |||||

| Top slide travel | 228 mm (8.98") | |||||

| Cross slide travel | 400 mm (15.75") | |||||

| Headstock & Main spindle | ||||||

| Spindle nose type | D1-11 | |||||

| Spindle center sleeve | MT#7 x MT#5 | |||||

| Spindle bore | Φ104 mm (4.094") | |||||

| Spindle speed | 12 steps | |||||

| Speed range (60 Hz) | 4P: 13, 20, 30, 47, 70, 105, 150, 230, 340, 530, 800, 1200 RPM | |||||

| Threads and Feeds | ||||||

| Whitworth threads kinds / range | 44 Kinds / 2 ~ 72 T.P.I. | |||||

| Metric threads kinds / range | 39 Kinds / 0.2 ~ 14 mm | |||||

| Diameter of leadscrew | Φ45 mm (1.77") | |||||

| Pitch of leadscrew | 4 TPI, P = 6 mm | |||||

| Longitudinal feeds | Metric: 0.035 ~ 0.98 mm / rev; INCH: 0.0012 ~ 0.039 / rev | |||||

| Cross feeds | Metric: 0.011 ~ 0.296 mm / rev; INCH: 0.0004 ~ 0.0117 / rev | |||||

| Tailstock | ||||||

| Quill diameter | Φ80 mm (3.15") | |||||

| Quill travel | 250 mm (10") | |||||

| Taper of center | MT # 5 | |||||

| Motor | ||||||

| Main spindle | Std.: 15 HP (11.25 kW) Opt.: 20 HP (15 kW) | |||||

| Coolant pump | 1/6 HP | |||||

| Measurement | ||||||

| Weight Approx | 60" | 2860 | 2950 | 3040 | ||

| Net weight (KG) | 90" | 3310 | 3400 | 3490 | ||

| 120" | 3545 | 3635 | 3725 | |||

| 160" | 4150 | 4240 | 4330 | |||

| 200" | 4600 | 4690 | 4780 | |||

| Packing size length | 3255 mm (128.14") / 4055 mm (159.64") / 4755 mm (187.2") / 5755 mm (226.57") / 6755 mm (265.94") | |||||

| Width x Height | Width: 1150 mm (45.27 "); Height: 1700 mm (66.9") | |||||

Specifications subject to change without notice.

Standard Accessories:

- Backplate for 12" chuck

- Dead center MT.5

- Dead center MT.5 with carbide tip

- Spindle center sleeve MT#7 * MT#5

- Level pads......6 ~ 10 pcs

- Tool set & Box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories:

3-Jaws scroll 12" / 16" chuck

4-Jaws independent 16 / 18" chuck

Faceplate 20"

Chuck Safety Guards

Electrical system for CE

Digital read out system

Carriage micro stop set

Drill chuck & arbor

Rotating center MT.5

Taper turning attachment

Steady rest w/ball bearing

Follow rest w/bronze tip

Quick change tool post

Protect cover on leadscrew for CE

- All castings are properly stabilized and stress relieved.

- Bed ways are hardened & ground to min. HRC48-55.

- Extremely low noise level.

- Foot brake pedal provided.

- Wider bed way which give absorbs vibration.

- Y-Δ type spindle motor equipped to make sure smooth start and operation.

- Oil distributor may be adjusted to lubricate bedways, cross slide, or both.

- Automatic and manual forced lubrication pump offered oil to bed ways and cross slide.

- Dual Braking System: A mechanical brake system plus an electrical braking system to make sure the operator could stop the spindle in the shortest time.

- 3V sliding ways provide more stable displacement and processing smoothness.

Rugged headstock

- Forced lubrication to all running points.

- Head housing features outstanding vibration dampening and deformation free performance.

- Rugged head construction gives extra rigidity and heavy cutting.

- All gears and shaft are hardened and precision ground.

Universal gearbox

- The universal type gear box provides a wide range of inch & metric threads without changing any gear for increasing convenience.

- Gears are hardened

- Oil bath lubrication in gear box

Heavy duty spindle

- Camlock type spindle

- Precision machined from forged alloy steel, hardened, precision ground and dynamically balanced.

- Three-point support by high precision taper roller and ball bearings eliminates chatter when performing heavy cutting.

Apron

- A manual & automatic lubrication system equipped to keep the sliding ways and bedways lubricated.

- Choice of right or left hand wheel.

- An overload protection device equipped to avoid machine damaged.

Rugged tailstock

- Tailstock quill is graduated in inch / metric scales.

- It has a tang slot for positive drive of tool.

- Two - step tailstock provide smoothly operation.