Total : 2

Products

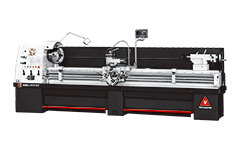

- Manual Lathe

- All Gear-Head Lathe

- Variable Speed Lathe

- Clutch Type Lathe

- CNC Lathe

- Flat Bed CNC Lathe

Subscribe Newsletters

-

Shun Chuan Precision Machinery Co., Ltd.

-

TEL:+886-37-741591(Rep.)

-

FAX:+886-37-741593

-

E-mail:info@sunmaster-cnc.com

© 2020 Copyright

Shun Chuan Precision Machinery Co., Ltd. All Rights Reserved.

- Designed by GTMC

- Taiwan Products

- B2BManufactures

- B2BChinaSources

- SMP Version

I agree