Manual Lathe

A conventional lathe machine, also known as an engine lathe machine or manual lathe machine, is a machine tool used in metalworking for various machining operations. It is a versatile and widely used tool that allows for the shaping, cutting, drilling, and turning of cylindrical workpieces.

Conventional lathes typically consist of a horizontal bed, a headstock at one end, and a tailstock at the other. The workpiece is clamped between the headstock and tailstock, allowing it to rotate about its axis. The cutting tool, held in a tool post, is then brought into contact with the rotating workpiece to remove material and shape it.

These lathes machines can handle various operations, including facing, turning, drilling, boring, threading, and taper turning. They are commonly used for manufacturing components such as shafts, bushings, pulleys, and other cylindrical parts. The versatility and precision of conventional lathes make them suitable for both small-scale workshops and large industrial settings.

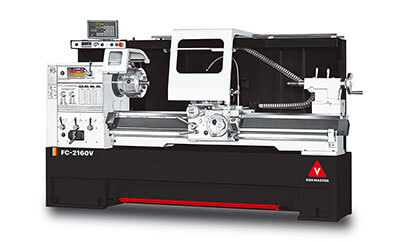

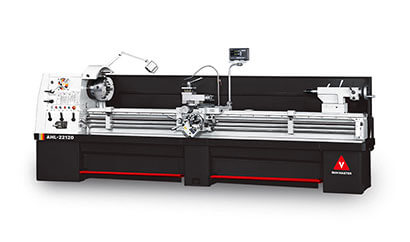

With a very skilled R & D team management, SHUN CHUAN® offers a large range of high-speed precision manual metal lathes, including All Gear-Head Lathe Machine, Variable Speed Lathe Machine, and Mechanical Clutch types Lathe Machine. From small size (13” swing over bed and 30” DBC) to middle size (30” swing over bed and 200” DBC), not only for educational purposes but also toolroom and general production line, our manual toolroom lathe machines could satisfy most demand of the job.

What is SHUN CHUAN® Conventional Lathes Machines Advantage?

- Cost-effectiveness: Conventional lathe machine are generally more affordable than CNC lathes. They have simpler designs and do not require sophisticated electronic controls and programming associated with CNC machines. This makes them a cost-effective option, particularly for small-scale workshops or businesses with budget constraints.

- Versatility: manual toolroom lathe machine are highly versatile and can perform a wide range of machining operations. They can handle tasks such as turning, facing, drilling, boring, threading, and tapering. With skilled operation and proper tooling, manual lathe machines can produce complex shapes and profiles on workpieces. Their versatility makes them suitable for both small-batch production and custom machining.

- Flexibility and Adjustability: Operators have full control over the cutting tool and the machining process in a conventional lathe machine. They can easily adjust the speed, feed rate, depth of cut, and tool position according to the specific requirements of the workpiece. This flexibility allows for on-the-fly modifications and adjustments, making engine lathe machines adaptable to different materials and machining needs.

- Skill Development: Operating a conventional lathe requires a certain level of skill and craftsmanship. Machinists who work with manual toolroom lathe develop a deep understanding of the machining process, tooling, and work-holding techniques. They gain hands-on experience in setting up, aligning, and operating the machine, honing their manual machining skills and problem-solving abilities. These skills can be valuable in various machining applications and provide a solid foundation for transitioning to CNC machines.

- Maintenance and Repair: Conventional lathes have simpler mechanical systems compared to CNC lathes machines, which can make them easier to maintain and repair. Their components and mechanisms are generally more accessible, and repairs or replacements can often be done without specialized knowledge or expensive components. This can result in reduced downtime and lower maintenance costs.

- Education and Training: Conventional lathe machines are commonly used in educational institutions and vocational training centers to teach machining principles and techniques. Learning manual lathe machines helps students understand the fundamentals of machining, including tool selection, feeds and speeds, and manual control. It allows them to grasp the core concepts before transitioning to more advanced CNC technology.