- Home

- Products

- Manual Lathe

- All Gear-Head Lathe

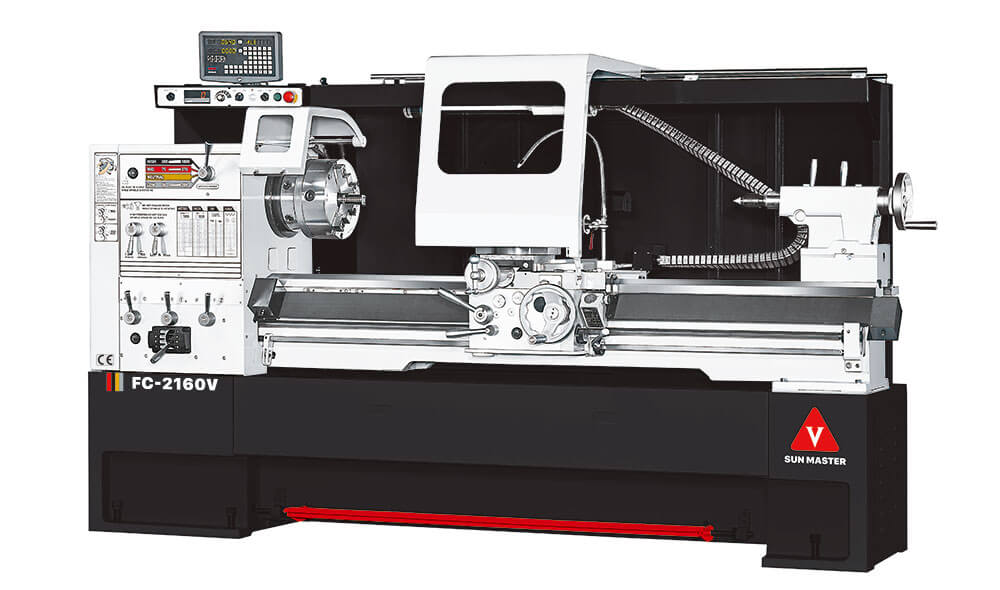

- FC Series Gear Head Conventional Lathe Machine

FC Series Gear Head Conventional Lathe Machine

| MODEL | FC-1640 | FC-1660 | FC-1840 | FC-1860 | FC-1880 | FC-2140 | FC-2160 | FC-2180 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Height of centers | 205 mm (8.07") | 231 mm (9.05") | 271 mm (10.67") | ||||||

| Swing over bed | 410 mm (16.14") | Ø462 mm (18.11") | Ø542 mm (21.34") | |||||||

| Swing in gap | 583 mm (22.95") | Ø650 mm (25.59") | Ø730 mm (28.74") | |||||||

| Swing over cross slide | 262 mm (10.3") | Ø305 mm (12") | Ø387 mm (15.23") | |||||||

| Distance between centers | 1000 mm (40") | 1500 mm (60") | 1000 mm (40") | 1500 mm (60") | 2200 mm (86.6") | 1000 mm (40") | 1500 mm (60") | 2200 mm (86.6") | ||

| Width of bed | 320mm (12.5") | |||||||||

| Headstock and Main Spindle | Spindle nose, internal taper | D1-8 / A1-8 (opt.), Ø85mm Taper 1/19.18 | ||||||||

| Spindle center sleeve | Ø85mm Taper 1/19.18 x MT. No.5 | |||||||||

| Spindle bore | Ø80mm (3.149") | |||||||||

| Spindle speed: Gear steps / Range |

12 steps / | |||||||||

| A | 26 | 40 | 60 | 90 | rpm | |||||

| B | 105 | 145 | 205 | 305 | rpm | |||||

| C | 510 | 715 | 1000 | 1500 | rpm | |||||

| Carriage | Cross slide travel | 250 mm (9.84") | 300 mm (11.81") | |||||||

| Top slide travel | 150 mm (5.9") | |||||||||

| Threads and Feeds | Whitworth threads: Kinds / Range | 45 kinds / 2~72 T.P.I.. | ||||||||

| Metric threads: Kinds / Range | 39 kinds / 0.2~14 mm | |||||||||

| D.P. threads: Kinds / Range | 21 kinds / 8~44 D.P. | |||||||||

| M.P. threads: Kinds / Range | 18 kinds / 0.3~3.5 M.P. | |||||||||

| Longitudinal feeds | 0.04~1.0 (0.0015"~0.04") | |||||||||

| Cross feeds | 0.02~0.5 (0.00075"~0.02") | |||||||||

| Tailstock | Quill diameter | Ø59 mm (2.322") | Ø68 mm (2.677") | Ø59 mm (2.322") | Ø68 mm (2.677") | |||||

| Quill travel | 127 mm (5") | 153 mm (6") | 127 mm (5") | 153 mm (6") | ||||||

| Taper of center | MT. No.4 | |||||||||

| Motor | Main spindle | std. 10 HP (7.5 kW) opt. 12.5 HP (9.375 kW) | ||||||||

| Forced lubrication for headstock | N/A | |||||||||

| Coolant pump | 1/8 HP | |||||||||

| Measurement | Weight Approx | NET | 1750kgs | 1900kgs | 1800kgs | 1950kgs | 2350kgs | 1850kgs | 2000kgs | 2400kgs |

| Packing size | GROSS | 1950kgs | 2150kgs | 2000kgs | 2200kgs | 2650kgs | 2050kgs | 2250kgs | 2700kgs | |

| Length | 2400mm | 2900mm | 2400mm | 2900mm | 3700mm | 2400mm | 2900mm | 3700mm | ||

| Width x Height | width 1155 mm (45.5") X height 1900 mm (74.8") | |||||||||

Specifications subject to change without notice.

Standard Accessories:

- Backplate for 10" chuck

- Dead center MT.5

- Dead center MT.4 with carbide tip

- Spindle center sleeve.Ø85mm Taper 1/19.18

- Level pads......6 pcs

- Tool set & Box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories:

3-Jaws scroll 10" chuck

4-Jaws independent 12" chuck

Faceplate 14"

Chuck Safety Guards

Electrical system for CE

Digital read out system

Carriage micro stop set

Drill chuck & arbor

Rotating center MT.4

Taper turning attachment

Steady rest w/ball bearing

Follow rest w/bronze tip

Quick change tool post

Protect cover on leadscrew for CE

- All castings are properly stabilized and stress relieved.

- Bed ways are hardened & ground to min. HRC48-55.

- Turcite B coating between the bed and carriage.

- Extremely low noise level.

- Foot brake pedal provided.

- Built-in coolant pump & fitting provided.

- Wider bed way which give absorbs vibration.

- Y-Δ type spindle motor equipped to make sure smooth start and operatrion.

Headstock

- Housing is vibration-absorbent, deflection-free.

- Gears are hardened & MAAG or REISHAUER ground.

Gear Box

- Universal type allowing a wide range of inch, metric, M.P., D.P. threads without change gears.

Apron

- R/H or L/H wheel can be available on request.

- Integrated automatic control for longitudinal & cross feeds, forward &reverse feeds.

Carriage & Slide

- Anti-Float design backlash eliminator fitted in cross slide nut.

- Safety clutch at feed shaft.

- Oneshot lubrication in carriage & top slide.

- Dual dials supply inchsystem screw.

- Metric dial supply metric system only.

Safety Features

- Nylon safety gears in end train.

- Shear pin in leadscrew.

Heavy Duty Spindle

- Machined from forged alloy steel, hardened ground & dynamically balanced.

- Three point support by high grade precision, machine tool taper roller & ball bearings.