- Home

- Products

- Manual Lathe

- All Gear-Head Lathe

- RML Series Gear Head Metal Lathe

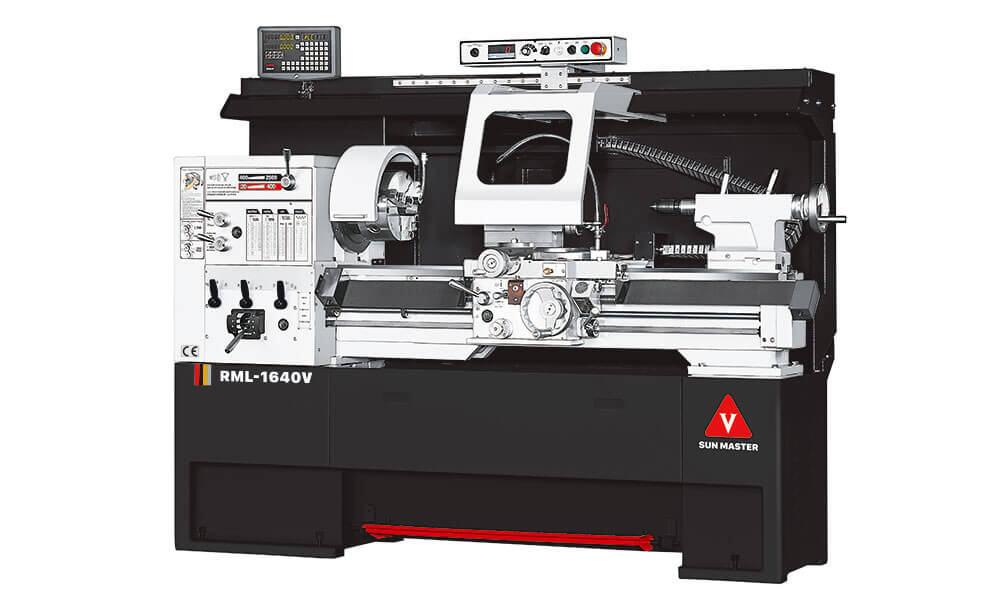

RML Series Gear Head Metal Lathe

| MODEL | RML-1430 | RML-1440 | RML-1460 | RML-1630 | RML-1640 | RML-1660 | ||

|---|---|---|---|---|---|---|---|---|

| Capacity | Height of centers | 180mm (7.08") | 205mm (8.07") | |||||

| Swing over bed | Ø360mm (14.17") | Ø410mm (16.14") | ||||||

| Swing in gap | - | Ø533mm (20.98") | - | Ø583mm (22.95") | ||||

| Swing over cross slide | Ø212mm (8.35") | Ø262mm (10.3") | ||||||

| Distance between centers | 800mm (31.5") | 1000mm (40") | 1500mm (60") | 800mm (31.5") | 1000mm (40") | 1500mm (60") | ||

| Width of bed | 260mm (10.236") | |||||||

| Gap width in front faceplate | - | 135mm (5.31") | 225mm (8.85") | - | 135mm (5.31") | 225mm (8.85") | ||

| Headstock and Main Spindle | Spindle nose, internal taper | D1-6 / A1-6 (opt.), MT. No.6 | ||||||

| Spindle center sleeve | MT. No.6 x MT. No.4 | |||||||

| Spindle bore | Ø52.5mm (2.066") | |||||||

| Spindle speed: Gear steps / Range |

8 steps / 70~1800 R.P.M. | |||||||

| OPT. | ||||||||

| 16 stepts / 8P 40~1000 R.P.M. | ||||||||

| 4P 80~2000 R.P.M. | ||||||||

| Carriage | Length on bed / Width of carriage | 513mm (20.19") / 412mm (16.22") | ||||||

| Cross slide travel | 220mm (8.6") | |||||||

| Top slide travel | 125mm (4.92") | |||||||

| Threads and Feeds | Whitworth threads: Kinds / Range | 45 kinds / 2~72 T.P.I. | ||||||

| Metric threads: Kinds / Range | 39 kinds / 0.2~14 mm | |||||||

| D.P. threads: Kinds / Range | 21 kinds / 8~44 D.P. | |||||||

| M.P. threads: Kinds / Range | 18 kinds / 0.3~3.5 M.P. | |||||||

| Longitudinal feeds | 0.05~1.7 (0.002"~0.067") | |||||||

| Cross feeds | 0.025~0.85 (0.001"~0.034") | |||||||

| Tailstock | Quill diameter | Ø52mm (2.047") | ||||||

| Quill travel | 152 mm (6") | |||||||

| Taper of center | MT. No.4 | |||||||

| Motor | Main spindle | 5HP4P OPT.5HP 4P / 2.5HP 8P | AC 3.7kW (5HP), Inverter | |||||

| Forced lubrication for HD. | - | |||||||

| Coolant pump | 1/8HP | |||||||

| Measurement | Weight (Net / Gross) Approx. | 1300kgs 1400kgs | 1350kgs 1470kgs | 1450kgs 1610kgs | 1350kgs 1450kgs | 1400kgs 1520kgs | 1500kgs 1660kgs | |

| Packing sizes | Length | 2070mm (81.5") | 2270mm (89.4") | 2785mm (109.7") | 2070mm (81.5") | 2270mm (89.4") | 2785mm (109.7") | |

| Width x Height | Width 1120mm (44.1") x Height 1900mm (74.8") | |||||||

Specifications subject to change without notice.

Standard Accessories:

- Backplate for 9" chuck

- Dead center MT.4

- Dead center MT.4 with carbide tip

- Spindle center sleeve MT.6

- Level pads......6 pcs

- Tool set & Box

- Operation manual & parts list

- Full length splash guard

- Halogen lamp

Optional Accessories:

3-Jaws scroll 9" chuck

4-Jaws independent 10" chuck

5C collet closer attachment

Driving plate with dog

Chuck Safety Guards

Electrical system for CE

Faceplate 12"

Digital read out system

Carriage micro stop set

Drill chuck & arbor

Rotating center MT.4

Taper turning attachment

Steady rest w/ball bearing

Follow rest w/bronze tip

Quick change tool post

- All castings are properly stabilized and stress relieved.

- Bed ways are hardened & ground to min. HS-70.

- Turcite B coating between the bed and carriage.

- Extremely low noise level.

- Foot brake pedal provided.

- Built-in coolant pump & fitting provided.

- CSS (constant surface speed control) on request for E.V.S. model.

- Wider bed way which give absorbs vibration.

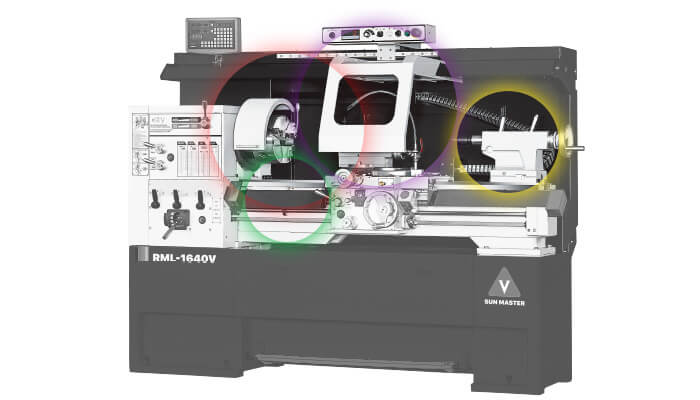

E.V.S. MODEL ELECTRIC CONTROL

- CE electric on request.

- The electric cabinet is sealed protected against entrance of water, dirt and other contaminants.

- A main disconnect switch provided.

- Electric 1/4HP pump for headstock pressure lubrication.

- Prolong life expectancy of gears and spindle.

- Combination of forced lubrication and oil bath system in headstock.

Heavy Duty Spindle

- Machined from forged alloy steel, hardened ground & dynamically balanced.

- Three point support by high grade precision, machine tool taper roller & ball bearings.

E.V.S. HEADSTOCK

- Forced lubrication to all running points.

- Hardened & ground gears and shafts.

- R.P.M. LED display indicator makes it easy to obtain the optional constant surface.

- Electronic control panel located on top head stock, with RPM display unit, speed control electric knob, emergency stop and motor start push button.

- Electronic infinitely variable speed with A.C. motor inverter.

- Two headstock gear speed ranges supply a high torque in low range from 20 up to 400 RPM and in high range from 400 up to 2500 R.P.M.